Product Description

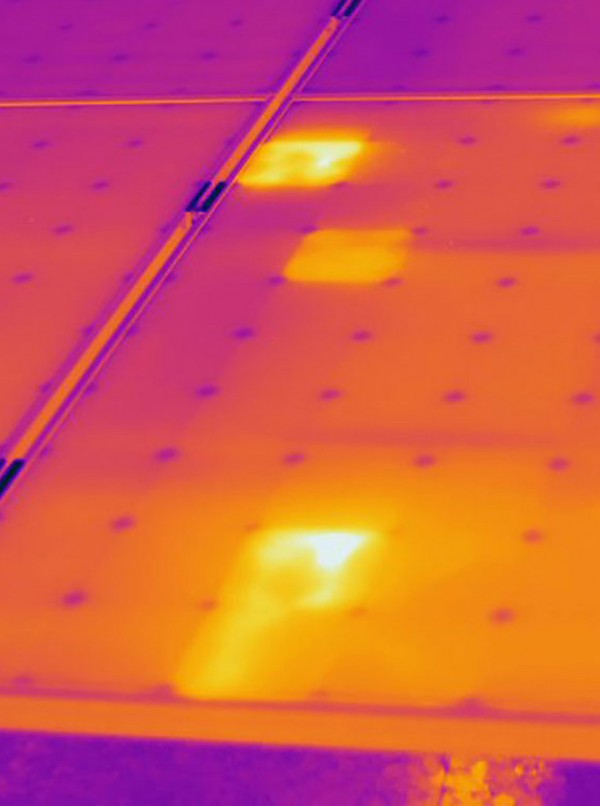

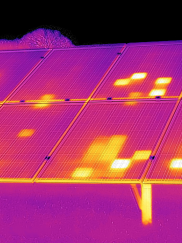

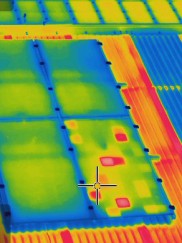

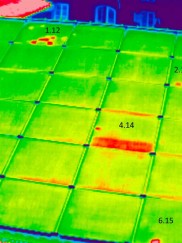

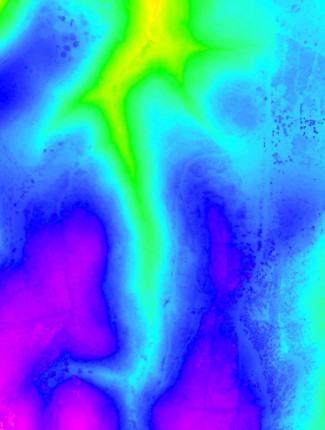

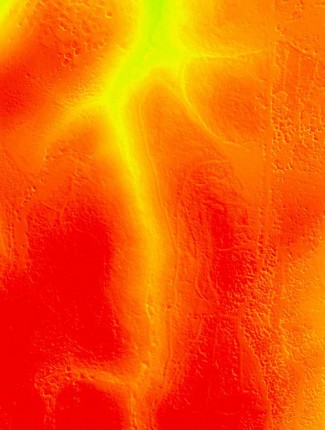

Thermography measures surface temperatures by using infrared video and still cameras. These tools see light that is in the heat spectrum. Images on the video or film record the temperature variations of the solar panel skin, ranging from white for warm regions to black for cooler areas.

As their temperatures rise solar panels become less efficient, producing less to break down or even produce a reverse current, which might damage the entire solar plant. Thermal imaging cameras can be used to detect hot spots in the panels from a distance, which makes it a lot easier to find defects before they become devastating breakdowns.

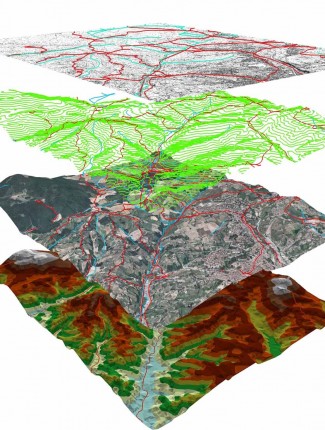

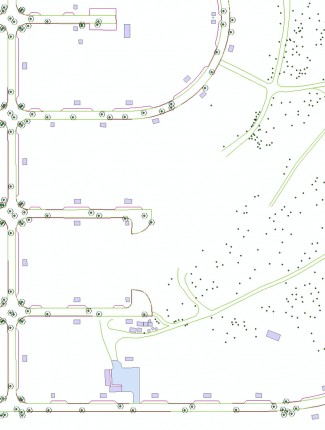

using a drone to execute such scans offers a quick and yet very accurate survey assuring specific action items

“When is the best time for a thermal evaluation?”

Terrascan labs highly recommends that your preventive maintenance and quality control monitoring starts with the installation phase, followed by regular checkups. Installation Phase Inspections of solar panels eliminates or recognizes immediately manufacturing defects of impurities, gas pockets or cracked cells. Regular checkups help to maintain the solar panels’ operational functionality and contribute to an extended lifetime. Solar Panel Inspections using thermal imaging has proven itself to drastically improve an owner’s return on investment.

Reviews

There are no reviews yet.